EDF-5.4 is a glass bioreactor with working volume till 4.5 l (total volume 6.2 l, inside diameter 150mm). The bioreactor is mounted on stainless steel pipeline legs.

It is foreseen for the cultivation of bacterial cultures, filamentous fungi, yeast, microalgae, mammalian cell cultures and stem cells. Depending on the applied microbial culture it is possible to adapt the configuration of the bioreactor in a corresponding way.

EDF-5.4 includes the following main parts and features:

- Completed bioreactor vessel with a novel upper magnetic drive. The range of mixer rotation speed is 40 - 1000 rpm;

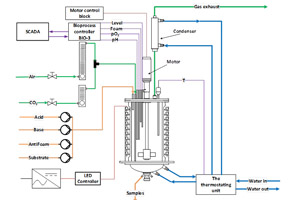

- Bioprocess controller BIO-4 controls pH, pO2, temperature, antifoam level, solution level, mixer revolutions in the Basic configuration, as well as additional parameters and operations according to the customer request. pO2 cascade control and time dependent feeding profiles are also included in the Basic configuration;

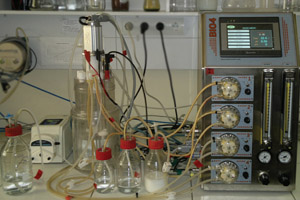

- Stainless steel "monoblock" construction, which contains the bioprocess controller BIO-4, the thermostat, peristaltic pumps, power control parts, gas supply and mixing (air, O2) units;

- Thermoregulation is carried out by circulation of thermostated water trough the jacket, which covers the bottom of the bioreactor;

- 4 free configurable peristaltic pumps;

- The possibility of wireless control using smartphones (iPhone and others) and tablet computers (iPad and others);

- Accessories for upper lid (needles, sparger, chemostat tube, ports for sensors, condenser with outlet filter and valve);

- Two rotameters for air and O2, inlet and exhaust air filters;

- A valve and a program module for O2 enrichment process;

- Temperature, foam and level sensors;

- A sterilizable pH sensor from Finesse (PHS-EFP-K8-325) or Mettler-Toledo (405-DPAS-SC-K85/325) with stainless steel protection covering and fittings;

- A sterilizable pO2 sensor from Finesse (DOS-OFF-D4-325) or Mettler Toledo (Inpro 6820/12/320) with fittings;

- Autoclavable sampling device in the bottom of the vessel;

- A frame for titration bottles (3);

- Other standard accessories to ensure full functionality of the fermentation process (bottles for titration liquids, tubes, spare parts etc.).

Optionally:

- A special mixer for mycelial and other shear sensitive microorganisms;

- A gas mixing system (O2, N2, CO2);

- A PC SCADA program for process data monitoring, data archiving and control. A special USB dongle key for seamless remote access to the SCADA system can be supplied.

- Application and integration of additional sensors (redox, O2 and CO2 in exhaust gas, gas flow rates, optical density and other);

- Automatic feeding control, using a supplement program, based on MATLAB;

- Customer specialised solutions for adapting to different microorganisms cultivation tasks.

Photobioreactor PBR is a glass autoclavable photobioreactor with working volume 2-4.5 l (total volume 6.2 l, internal diameter - 150 mm). The bioreactor is used for precise phototrophic cultivation of algae and cyanobacteria.

Automation System

- Stainless steel monoblock construction. In monoblock are included: bioprocess controller BIO-4, thermostat, peristaltic pumps, power parts, LED control, gas supply (air, CO2) and mixing unit.

Bioprocess controller BIO-4:

- Colored 5.6" touch screen display,

- Controls of pH, pO2, temperature, foam, level,

- Remote control of the experiment via internet (SCADA Control System)

- Data collection in real time.

- Data visualization in graphs.

- Display of all process data, (t, ph, pO2, etc.)

- CO2 addition via pH control or manual gas control

- LED-illumination;

- Control of the illumination intensity as a time dependent profile program;

- Day/night cycles;

- Intensity control - 0 to 100% PWM (0 to 1500 µmol/m2/s);

- The thermoregulation is carried out by circulation of thermostated water through a jacket in the photobioreactor bottom

- Both static and Day-night temperature control

- Mixing system for mycelial or other shear sensitive microorganisms consisting of 2 mixers with 3 pitched-blades.

- Peristaltic pump for Chemostat mode cultivation, i.e. programed addition of substrate and other substances.

EDF-15.1 is a glass bioreactor with working volume till 10 l (total volume 16 l, inner diameter 200mm). The bioreactor is mounted on stainless steel pipe legs.

It is foreseen for the cultivation of bacterial cultures, filamentous fungi, yeast, mammalian cell cultures and steam cells. Depending on the applied microbial culture it is possible to adapt the configuration of the bioreactor in a corresponding way.

EDF-15.1 includes the following main parts and features:

- Completed bioreactor vessel with a novel upper magnetic drive. The range of mixer rotation speed is 40 - 750 rpm;

- Bioprocess controller BIO-4 controls pH, pO2, temperature, antifoam, level, mixer revolutions in the Basic configuration, as well as additional parameters and operations according to the customer request. pO2 cascade control and time dependent feeding profiles are also included in the Basic configuration;

- Stainless steel "monoblock" construction, which contains the bioprocess controller BIO-4, the thermostat, peristaltic pumps, power control parts, gas supply and mixing (air, O2) units;

- Thermoregulation is carried out by circulation of thermostated water trough the jacket, which covers the bottom of the bioreactor;

- 4 free configurable peristaltic pumps;

- The possibility of wireless control using smartphones (iPhone and others) and tablet computers (iPad and others);

- Accessories for upper lid (needles, sparger, chemostat tube, ports for sensors, condenser with outlet filter and valve);

- Two rotameters for air and O2, inlet and exhaust air filters;

- A valve and a program module for O2 enrichment process;

- Temperature, foam and level sensors;

- A sterilizable pH sensor from Finesse (PHS-EFP-K8-425) or Mettler-Toledo (405-DPAS-SC-K85/425) with stainless steel protection covering and fittings;

- A sterilizable pO2 sensor from Finesse (DOS-OFF-D4-425) or Mettler Toledo (Inpro 6820/12/425) with fittings;

- Autoclavable sampling device in the bottom of the vessel;

- A frame for titration bottles (3);

- Other standard accessories to ensure full functionality of the fermentation process (bottles for titration liquids, tubes, spare parts etc.).

Optionally:

- A special mixer for mycelial and other shear sensitive microorganisms;

- A gas mixing system (O2, N2, CO2);

- A PC SCADA program for process data monitoring, data archiving and control. A special USB dongle key for seamless remote access to the SCADA system can be supplied.

- Application and integration of additional sensors (redox, O2 and CO2 in exhaust gas, gas flow rates, optical density and other);

- Automatic feeding control, using a supplement program, based on MATLAB;

- Customer specialised solutions for adapting to different microorganisms cultivation tasks.

The EDF-5.4 monoblock can be adapted for single use bioreactor control. For example, we have expierence in application of single use vessels from CerCell (Danmark).

CerCell has configurable vessels of different volumes (0.5 to75 liters). These vessels are equipped with all necessary accessories to provide fermentations of different microbial cultures. An important advantage of these vessels is the possibility to achieve high mixer rotation speeds. For example, 7.5 liter bioreactor, equipped with 3 ruchton turbines, can achieve mixer rotation speed up to 1500 rpm. In SUB it is possible to apply both single use and sterilizable pH and pO2 sensors.

The application of SUB has following advantages:

- Decreases the risk of contamination;

- Eliminates the necessity to acquire and maintain the infrastructure for the processes (cleaning and sterilisation), which can be critical for validation;

- Simplifies and reduces validation costs;

- Reduces the costs of labor expenditures for the preparation operations (assembling - disassembling, cleaning and sterilization);

- The possibility to develop the fermentation processes according GMP requirements.

We have tested 7.5 liter vessel from CerCell in fed-batch cultivation of E.Coli. Obtained results were comparable with fermentations in a laboratory scale autoclavable glass bioreactor.

We offer stainless steel bioreactors from 20 to 15000 liters, as well as bioreactor lines, including other technological vessels. An autonomous bioreactor consists of 3 main parts:

- Bioreactor vessel;

- Technological stand;

- Control cabinet, including PLC.

The connections between the bioreactor vessel and the technological stand are implemented with the help of flexible parallel wrapped stainless steel tubes.

To ensure fully automated in-situ sterilization process, it is necessary to install pneumatically controlled membrane valves in the bottom, the inlet of a sparger and the lid of the vessel.

The bioreactor vessel

The fully equipped stainless steel bioreactor vessel (sterilizable in place) with upper or lower magnetic drive for agitation with 2 – 3 standard rushton turbines (pitched blade or marine mixer optionally). For all vessels H:D is in the range of 1:1.5 to 1:3. It can be specified in certain limiting sizes. For all vessels the maximal design pressure inside the vessels – 3.0 bar, in jacket – 3.5 bar. Maximal temperature – 1400C. Inner vessel wall: surface roughness lower than 0.4µm.

Outer vessel wall: surface roughness – 0.63 µm (pickled & passivated).

The material of the parts, contacting with product is stainless steel 316L. For parts, not contacting with product (for example, jacket), – stainless steel 304. All bioreactors have insulation over the jacket. The outside surface of insulation is covered by stainless steel 304.

The aeration system includes a ring sparger with maximal flow rate of 2 vvm.

DN=25mm ports according to Ingold standard are installed in the lower cylindrical part for inserting sterilizable pH, pO2 and temperature sensors, as well as a DN=25mm port according to Ingold standard for the sterilizable sampling device.

A stainless steel membrane pressure sensor (Endress+Hauser) and a pneumatically controlled membrane valve are placed in the bottom of the vessel.

In the upper cylindrical part there is a longsided sight glass.

Following accessories are placed in the lid of a basic configuration: Membrane pressure manometer, safety valve, needles with membrane valves for titrating (2-4), sight glasses with lighting, overpressure sensor with control signal (Endress + Hauser), foam and level sensors, CIP washing head, additional sanitary tri-clamp based connections.

Technological stand

Technological stand includes pipeline connections for supply of air, purified water, steam, purofied steam, as well as for filtration of air, thermostating, sterilization, sampling and discharging. A group of pneumatically controlled valves ensures fully automatic control of sterilization and thermostating. Inlet and outlet air supply filters (PALL), as well as air pressure control system and stainless steel air supply control rotameter (MFC and system of O2 enrichment – as options) are also installed in the stand.

The technological stand is connected to the control cabinet, providing the following fully automated processes:

- Temperature control in the bioreactor vessel through jacket by heating or cooling. The heating is possible with the help of electrical heating or steam injection;

- Pre-heatingthe vessel with the help of steam injection;

- Coolingthe vessel after sterilization;

- Sterilization of the empty vessel, includingof inlet and outlet air filters;

- Sterilization of the vessel containing substrate;

- Separate sterilization of the air filters.

The processes, including also all sterilization variants, are fully automated.

Control cabinet

Power control cabinet is made of stainless steel (RITTAL, Germany) and includes PLC based on Siemens Simatic series S7-300.

The following parameters are controlled in basic version:

- Temperature;

- рН;

- рО2;

- lower and upper static pressure; (foto 21129)

- foam;

- upper emergency liquid level.

There is an additional possibility to connect:

- Off-gas O2, CO2 and ethanol/ methanol concentration measurements;

- Overpressure control of in the vessel;

- Additional peristaltic pumps;

- Mass flow controllers (MFC);

- Additional gas supply and mixing (O2, N2, CO2).

The PLC can be connected to Profinet and Ethernet networks for communication with other devices (bioreactors, CIP/SIP, SCADA and etc.). The PLC allows selecting of the following processes control:

- Fermentation;

- Different variants of sterilization (SIP);

- Pre-heating;

- Cooling;

- CIP;

- Loading and discharge of the substrate or biomass.

With the help of user friendly operator interface the following process preparation and control operations can be provided:

- Adjusting of set points;

- Sensor calibrations;

- Process and devices Configuration;

- Graphical presentation of the process;

- Adjusting and displaying the state of alarms;

- Start / stop of selected processes;

- Working mode of devices (manual, automatic or the profile according to time );

- Adjusting of substrate feeding profile;

- The determination of access level for every user.